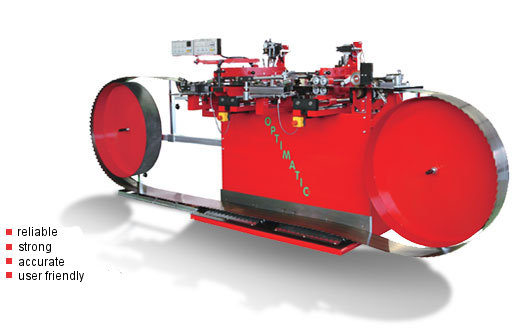

Optimatic Automated Bench, the AB, is your ticket to higher productivity and improved saw performance.

Reducing target size is a great opportunity to increase fiber yield. One key to reducing target size is to reduce saw performance variability thru running properly benched saws (flat and evenly tensioned) on a well maintained mill.

Optimatic Automated Bench takes care of the "properly benched" part, all while improving Filing Room productivity. The AB simultaneously levels and tensions the saw, just as a man would. And it performs this task while measuring to .0004" across the entire area of the saw - length and width. Tension is uniformly replenished.

Back is consistently maintained. Level is dead flat. And most importantly, the saws' Tire Line is accurately established throughout the entire length of the saw - more so than even possible by hand.

The even, consistent tire line allows a well pointed saw to operate at higher feed rates and higher quality levels, because the tendency to follow grain swirls and log inconsistencies is reduced.

| Connection value: | ||

|---|---|---|

| Electrical connetion: | 400 V 50 Hz or special voltage | Air Pressure: | 1/4″ Gas thread | Air: | Minimum 5 bar air consumption, 0,7 liter per stroke | Saw blade diameter: | Saw Wide: | From 80 mm to 300 mm wide or special up to 420 mm | Saw Long: | From 6 m | Saw Thickness: | 0.7 mm to 2.7 mm adjustable gauge unit easy to handle for four different saw gauge | Leveler tolerance: | 0,02 mm | Tensioning tolerance: | 0.02 mm differet to template | Tensioning: | By changing template different tensioning shape possible | Back gauge: | By setting back indicator can be rolled back, straight or convex | Control: | Microprocessor control | Working time: | 206 mm x 10 m ca. 50 Min | Dimensions: | Length without Saw supports: | 2200 mm | Height: | 1540 mm | Width: | 1115 mm | Working position: | 1110 mm | Weight: | 1120 kg |